The business, founded in 1985 by Stefano Bogo, a refrigeration technician at Costan in Limana after a stint in the family business, took its first steps in a garage next to his home in Castion, a small hamlet in the municipality of Belluno.

The first dividing machine was made by the entrepreneur himself, recovering and hand-assembling parts of disused machine tools.

In 1986, there was a move to a small shed, 150 metres away. Also in that year, on invitation, his colleague and friend Piergiorgio Fagherazzi joined the company. With his skills in economics and business, he enabled the company to make a quantum leap in a short time.

Piergiorgio also works at Costan as a technician: after specialising in refrigeration engineering at Itis, he is appointed by the company to organise courses for refrigeration technicians. He spends the morning equipping the area and the afternoon as a lecturer and instructor. Between the two they understand each other instantly.

The two figures, one more oriented towards the technical aspect and the other towards management dynamics, merge into an unstoppable and close-knit team.

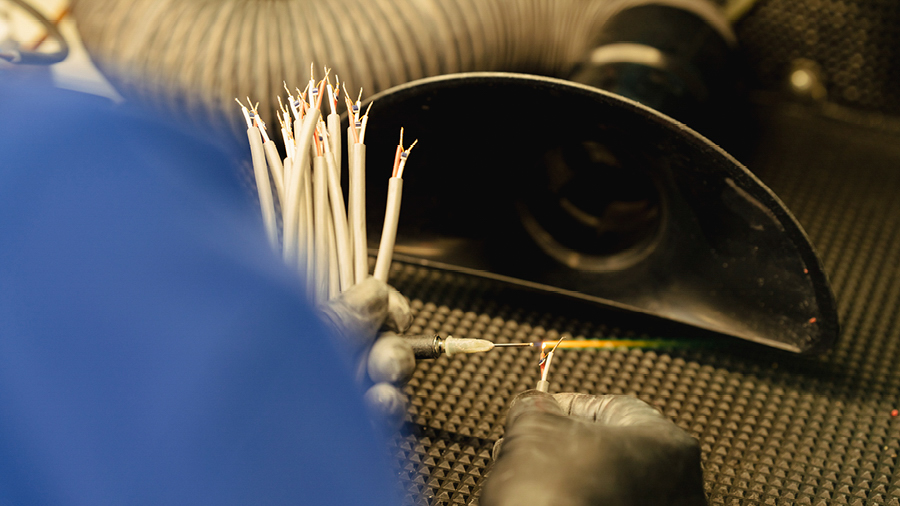

The realisation and implementation of the co-moulding process was the Made in Italy response to the adoption of new industry standards initially developed in Japan and Korea. Technological solutions, developed in Val Belluna, that to date have no competition in terms of quality and cost.

Challenges, these, that motivated the owners and R&D department to initially identify side solutions that were replicable and therefore compatible with mass production, while respecting the quality tolerances imposed by a strict market that is built on the precision of environmental measurement.

The challenge ahead can be summed up in the concept of 'sustainability'.

For Sacet, it is not just a word, it is a concrete commitment: environment, ethics and governance.

Which support the industrial imprinting for a better future.

We assist the customer by recommending the best available solution for the required application. The probe is designed, rendered on a data sheet, industrialised with the issue of a bill of materials and work cycle. The batch ordered is identified and tracked through production. Specific work steps are dedicated for inspection of the semi-finished product and testing of the finished product.

Sacet Srl produces exclusively to customer order. Materials are procured through two requirement analyses, MRP for low-rotating and Kan Ban (electronic) for high-rotating. Storage takes place in dedicated areas depending on the volumes handled, at the station and in specific supermarket warehouses for line feeding. Semi-finished product and product handling takes place with special trolleys and in boxes.

We have an in-house laboratory for analysing and studying products before they are placed on the market: all testing operations are tested and perfected here. Over the years, special attention has been given to investing in high-level instrumentation such as data loggers, climatic chambers, ovens, multimeters and microscopes. Our priority is to provide the best solution to your needs.

Sacet Srl's flagship is the production of most of its catalogue items via 8 automatic lines. The lines, developed to Sacet's design, provide for the even complete construction of the finished product, with high quality standards.